"An innovative solution for the removal of PFAS in complex waste streams"

Per- and poly-fluoroalkyl substances (PFAS) represent a challenging pollution concern all over the world posing a significant risk to human health and the environment. As PFAS chains do not break down easily, the compounds are now being detected in industrial wastewaters, landfill leachate, and wastewater treatment plants.

Concerns about PFAS contamination from landfills are driving wastewater treatment plants to stop receiving leachate unless effective pretreatment is completed.

PFAS removal from landfill leachate is particularly difficult to treat due to the complex chemistry, inconsistent feed quality, suspended solids and varying flow rates. Current options are limited and typically require comprehensive and expensive pre-treatment.

Our Solution

LMS has partnered with The Water and Carbon Group (WCG) to offer its LEEF System® as a low-energy PFAS extraction and volume reduction system. Based in Australia, WCG developed the LEEF System® to treat highly contaminated wastewater such as landfill leachate or brine streams from industrial or mining activities. A key feature is that pre-treatment is typically not required for direct PFAS removal.

The LEEF System® (Low Energy Evaporative Fractionation) is an innovative solution for the removal of PFAS from complex waste streams using minimal energy and no chemicals or consumables. Utilizing foam fractionation, the system removes up to 100% of targeted compounds and is effective without costly pre-treatment.

The LEEF System® is modular, so it is easy to scale up to fit a facility’s treatment needs. This flexibility allows the system to be customized to meet site-specific challenges for different leachate characteristics and flow. The flexible and robust modular system can be assembled to treat any volume from 5,000 gpd to 500,000+ gpd. The technology has already been successfully deployed at a landfill leachate treatment plant in the northern Australian city of Darwin, treating 36,000 gallons of complex leachate each day, in a zero liquid discharge operation.

The LEEF System® Benefits:

• Direct PFAS Removal Without Pre- treatment

• Removal to Limit of Detection

• Flow Rates 7,500 gpd to 250,000 gpd

• Below 1% Waste Stream

• Multiple Treatment Capacities

• Multiple Project Delivery Methods

• Low Energy & Operational Requirements

• Easily Scalable & Modular

To show capability in the US, WCG constructed a mobile demonstration-scale system that consists of four fractionators housed in a 40-foot shipping container that can be easily deployed throughout the country.

Since Summer 2022, WCG and LMS have been successfully removing PFAS from highly contaminated landfill leachates, including reverse osmosis concentrate (RO reject), during demonstration trials for some of the largest solid waste companies in the country. Check out the results below!

Case Study #1: Demonstration at a Tennessee Landfill

The first demonstration was completed at a Tennessee landfill to treat three diverse raw leachates and one RO reject. The streams were highly co-contaminated including:

Ammonia ranging from 380 mg/L to more than 3,800 mg/L

Total Dissolved Solids (TDS) between 5,700 mg/L and 50,800 mg/L

Chemical Oxygen Demand (COD) from 3,600 mg/L to over 24,000 mg/L

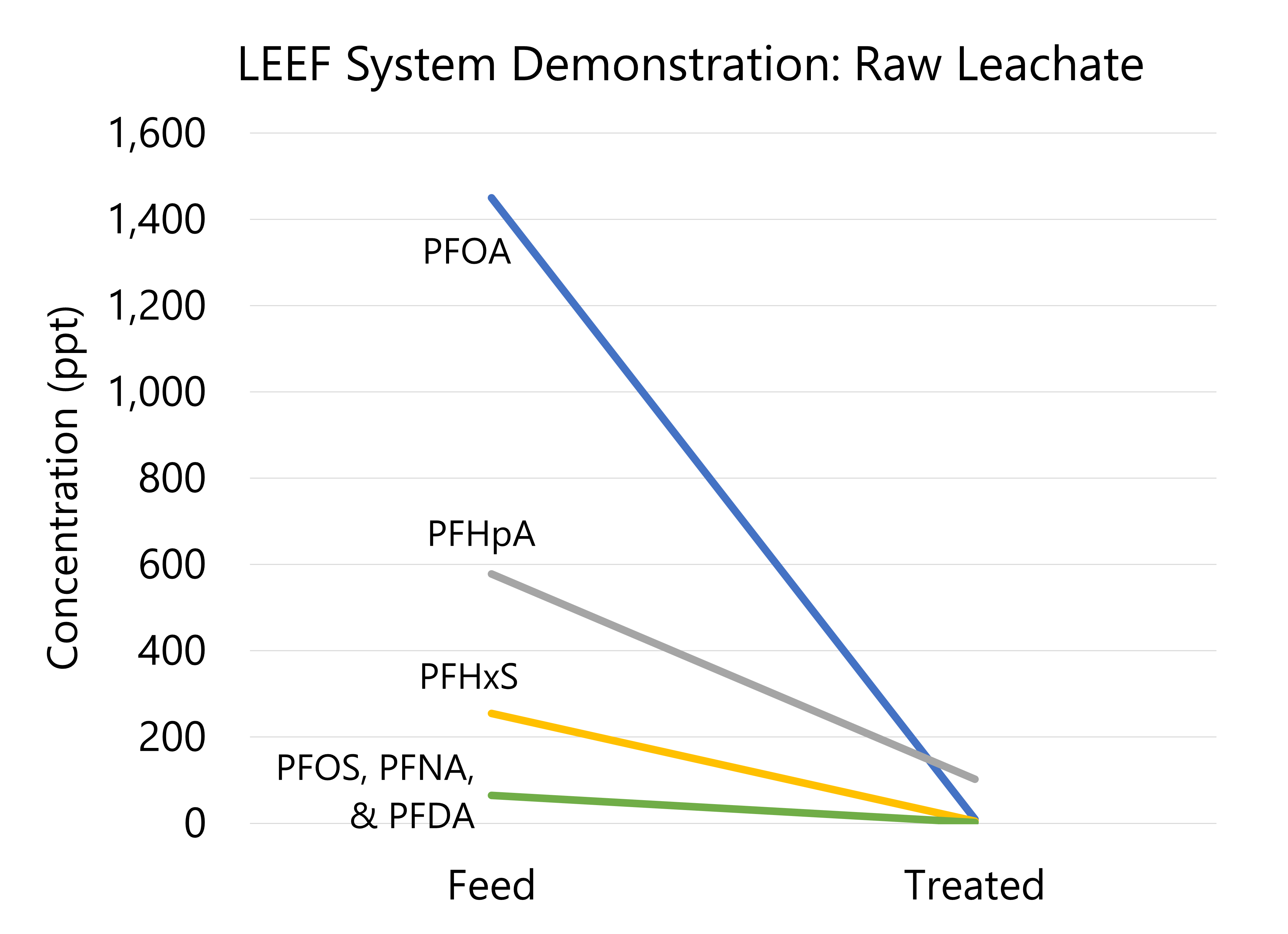

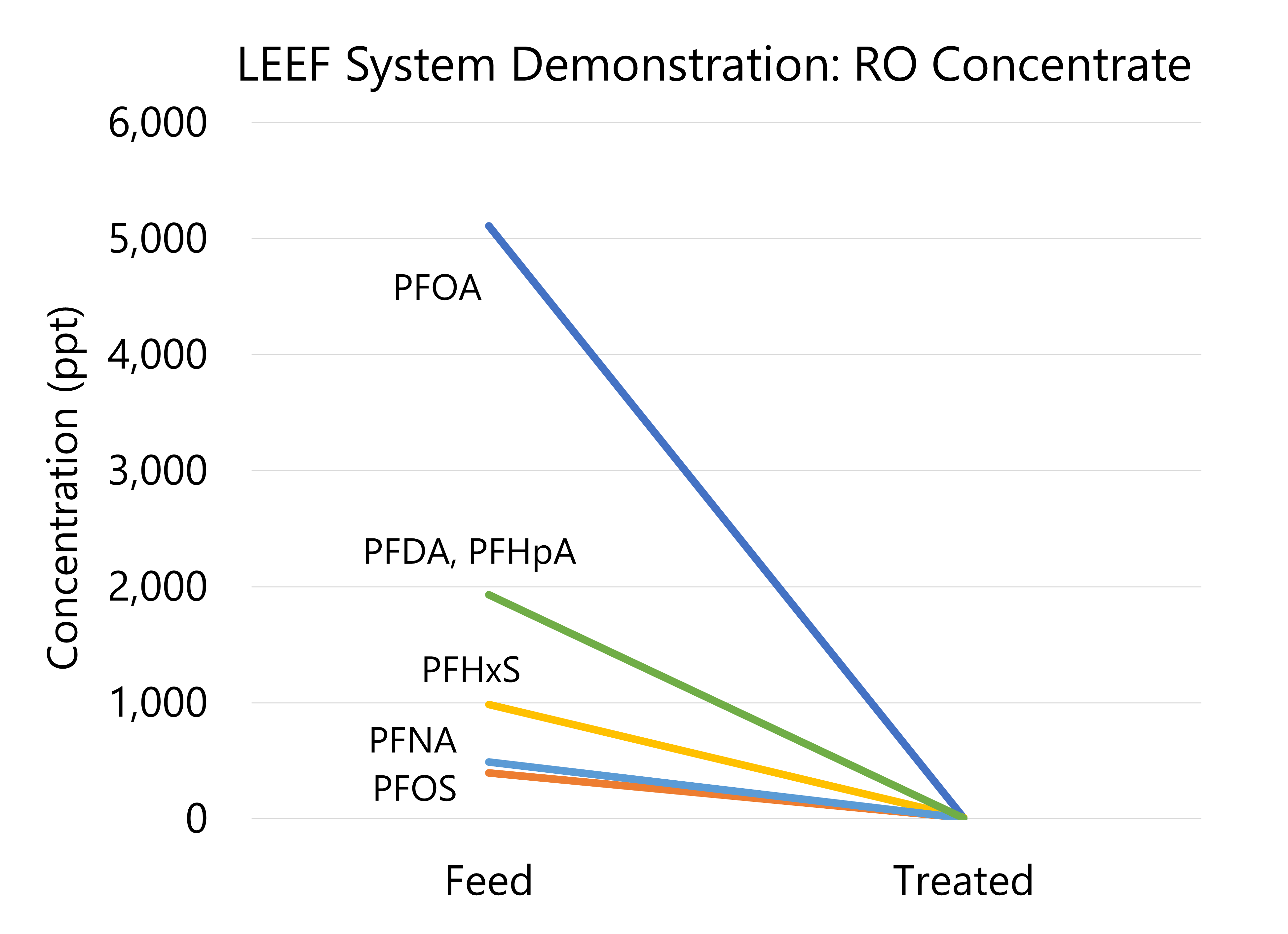

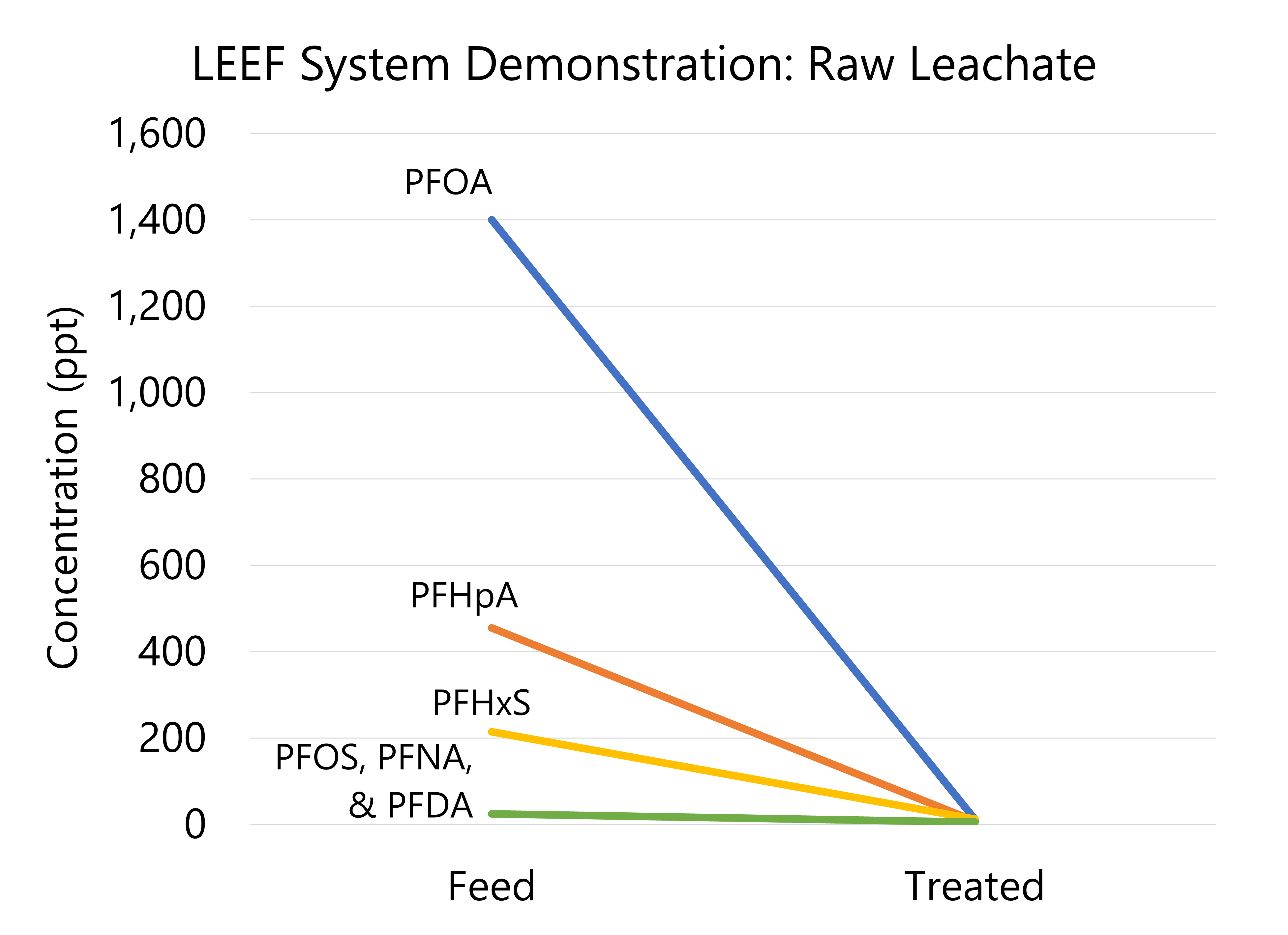

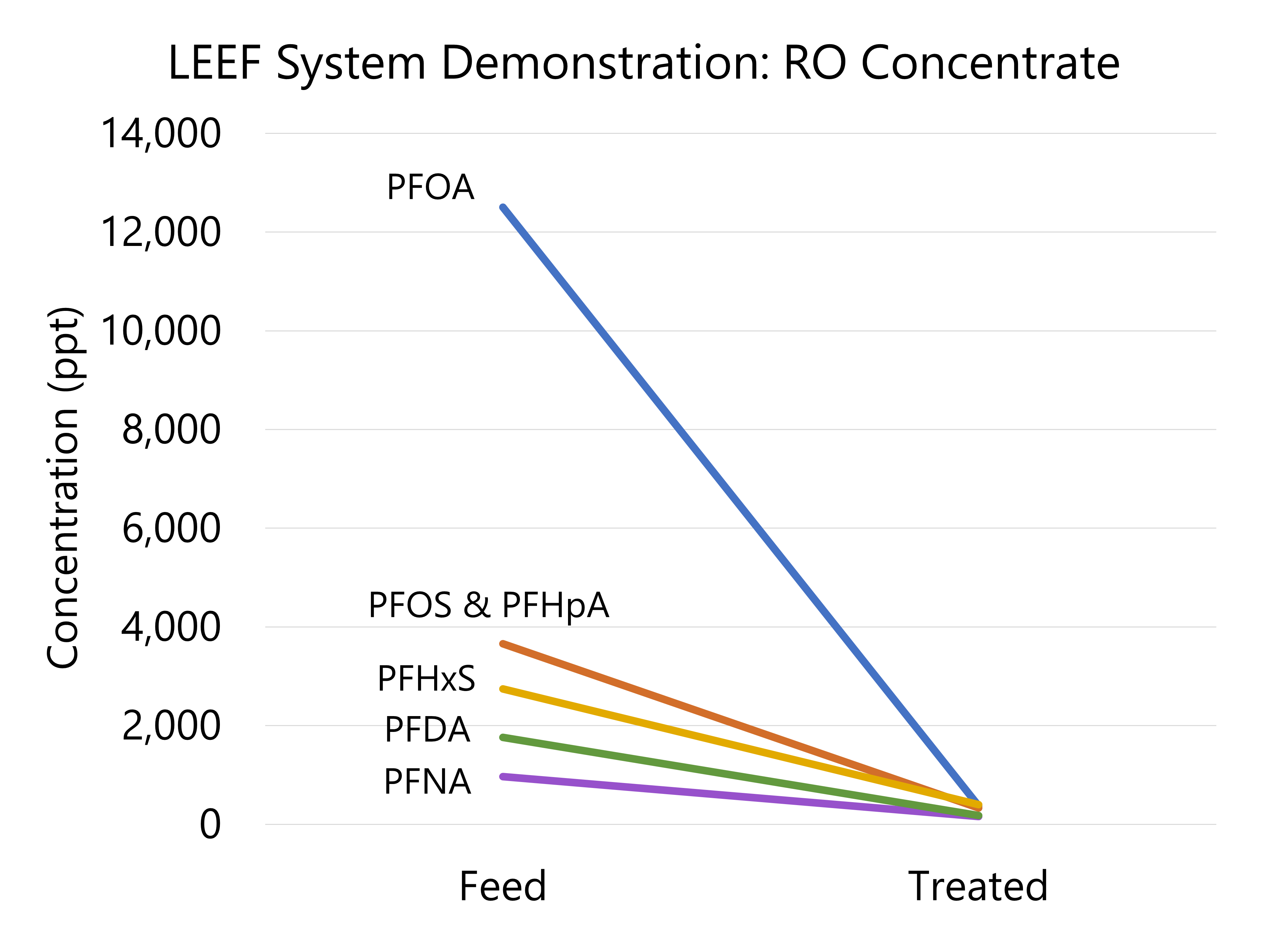

PFOA was between 1,400 ng/L and 5,100 ng/L and PFOS from 68 ng/L to nearly 400 ng/L.

The Tennessee demonstration was a success with the LEEF System® consistently removing PFAS compounds to below limits of detection, which ranged from <4 to <369 ng/L, while concentrating them into the small volume of foamate.

PFOA in the RO reject was reduced from 5,110 ng/L to <8.85 ng/L as its foamate reached 233,000 ng/L, clearly indicating a highly successful removal.

Interestingly, PFOS in one of the raw feeds started out as non-detect at <333 ng/L and ended up enriching in the foam to 37,800 ng/L, proving the LEEF System® is indeed capturing the compounds, even if initial raw concentrations are below laboratory detection limits.

The resulting foamate was between 0.5% and 2.0% of the initial raw influent volume. Foamate generation is highly influenced by background surfactants in the leachate, and physical characteristics such as temperature. Foamate can be further concentrated in a full-scale system through additional site-specific design components including additional foam fractionation concentration, alternative vessel orientation, and its solar distillation feature.

In addition to priority compounds, the Tennessee demonstration revealed the LEEF System® was able to deplete other PFAS that were initially present in the leachate streams, such as PFBS, PFHxA, PFDoA, PFHpS, 6:2 FTS, 5:3 FTCA, 7:3 FTCA, and others.

Case Study #2: Demonstration at a Virginia Landfill

The second demonstration was completed at a Virginia landfill for another leading solid waste company. We treated five diverse leachates, including an RO reject, that were highly co-contaminated with:

- Total Nitrogen ranging from ~500 mg/L to more than 3,000 mg/L

- Total Dissolved Solids (TDS) between ~14,000 mg/L and 54,000 mg/L

- Chemical Oxygen Demand (COD) from ~2,000 mg/L to 84,000 mg/L

- Alkalinity ~1,500 mg/L to 11,600 mg/L

- PFOA was between ~140 and 12,500 ng/L

- PFOS ranging from <10 ng/L to over 3,600 ng/L

The demonstration LEEF System® treated the five diverse leachates and RO reject successfully, shown by consistently removing PFAS compounds to below limits of detection, which ranged from <2 to <398 ng/L.

Test results included (all in ng/L):

- PFOA in raw RO reject: 8,300

- Treated: <11

- Foamate: 217,000

- PFOA in raw leachate: 2,080

- Treated: <4.4

- Foamate: 11,700

- PFHpA in raw leachate: 398

- Treated: 4.9

- Foamate: >4,500

- PFOS in raw RO reject: 659

- Treated: <10

- Foamate: 6,000

- PFHxS in raw RO reject: 1,990

- Treated: <11.9

- Foamate: 78,200

In addition to priority compounds, the demonstration was able to deplete other PFAS that were initially present in the leachate streams, including PFBS, PFHxA, 6:2 FTS, 5:3 FTCA, and others.

Case Studies #3 and #4: Two Demonstrations in Southeastern US

We just wrapped up our third and fourth demonstrations in the Southeastern US and will post results as soon as we can. Stay tuned!

To learn more about the LEEF System®, visit our website dedicated to the technology, or to arrange a demonstration at your site in the United States, contact us.